Chemical pumps play an essential role in many industries. They allow for the secure and efficient transfer mixing and dispensing of chemicals. Pumps specifically designed to handle Abrasive and corrosive liquids which are not compatible with standard pumps. Chemical pumps can be divided into positive displacement or centrifugal pumps.

By partnering with reputable chemical pump manufacturers, you can access top-quality chemicals that are in line with the standards of the industry. The manufacturers use their knowledge to create chemical pumps that are durable and durable, as well as efficient and economical. They make use of advanced technology and materials to create pumps that can stand up to the tough chemical. When working with trusted suppliers they can obtain pumps that are designed to withstand harsh conditions and perform optimally.

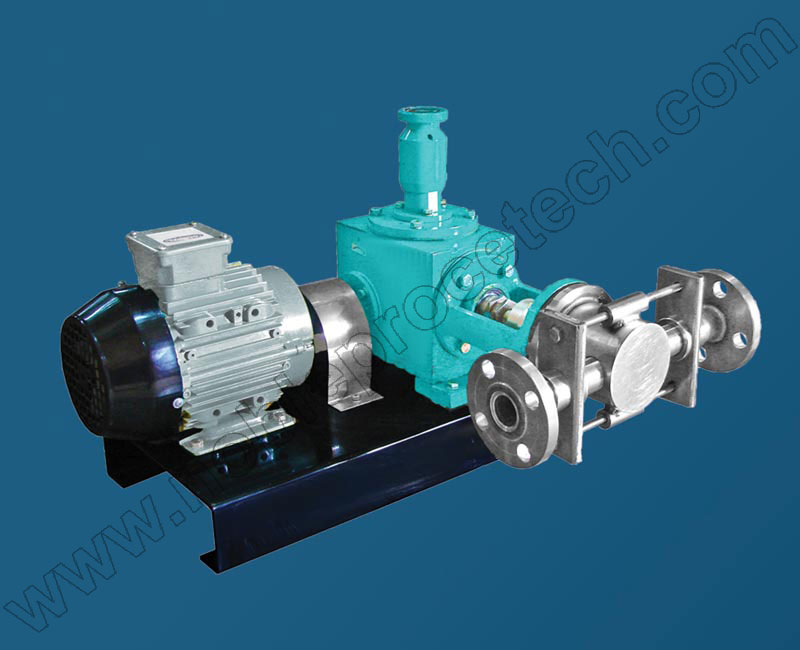

Chemical transfer pumps are designed specifically for fluid transfer. These pumps are designed to handle a broad range of chemicals like acetic acid, sulphuric acid as well as sodium hypochlorite and more. With an emphasis on effective fluid handling, chemical transfer pump makers design pumps that have features like corrosion-resistant material seals, leak-proof seals, as well as precise flow control systems. They are made to facilitate fluid, safe, and precise chemical transfer.

Chemical pump providers are essential in helping businesses locate the best pumps to meet their requirements. They provide a vast selection of chemical pumps from reputable manufacturers. These suppliers offer comprehensive product catalogues as well as technical knowledge to help businesses choose the right pumps for their application. Chemical pump manufacturers offer many options for businesses, so that they can select the ideal pump for their needs.

The significance of reliable chemical pumps goes beyond the protection of fluids. These pumps are essential for maintaining the safety and integrity of an whole industrial process. Pumps that are not reliable or functioning properly can result in costly leaks, inefficient operation, or even hazards. In the industries where chemicals are utilized, such as the chemical manufacturing or petrochemical industry, the consequences of the failure of a pump can be catastrophic. For more information, click chemical transfer pump manufacturer

Businesses can lessen the risks of handling fluids through the use of reliable chemical pumps. The pumps are designed to withstand the corrosive properties of various chemical substances. This ensures that they remain in operation efficiently and effectively over the course of time. They are constructed with solid materials, sophisticated seal mechanisms, and exact flow control. All of these characteristics contribute to a secure and reliable fluid transfer.

Furthermore, many chemical pumps are accompanied by comprehensive support and maintenance. The manufacturers and suppliers are aware of the importance of chemical pumps and provide technical support, spare part availability, as well as maintenance checks. This proactive approach can help identify and resolve any problems prior to them becoming serious, ensuring continued pump reliability and minimizing unplanned downtime.

Chemical pumps can be used in a variety of industries, including chemical manufacturing, food processing and Petrochemicals. They are crucial for fluid transfers, mixing and dispensing in these sectors. Chemical pumps are commonly employed for high-temperature heaters as well as in off-site applications at refineries. Their capacity and flexibility to manage challenging fluids make them vital tools in ensuring efficient and reliable industrial processes.

When choosing a chemical pumps It is vital to take into consideration factors like the kind of fluid, flows requirements, operating conditions and compatibility with chemicals. Trustworthy suppliers and chemical pump manufacturers provide guidance and assistance when choosing the best pump for a specific application. It is crucial to consider safety, efficiency, and the reliability of the pump when making a decision to reduce the risk of accidents, optimize productivity, and minimize downtime.

Chemical pumps are employed in refineries for a range of purposes. The pumps are able to serve a vital role in the off-site operation, facilitating the safe and effective transfer of chemicals in different contexts. When it comes to transporting corrosive liquids to storage facilities, or facilitating the loading and unloading of tanker trucks, or aiding in maintenance and repair, chemical pumps are indispensable to ensure that operations run smoothly beyond the refinery’s limits. The dependability, durability, and specialization of these pumps make them essential equipment for applications off-site, where the handling of harsh chemicals or corrosive ones requires accuracy, efficiency, and security. Chemical refineries can enjoy an efficient and seamless chemical transfer by investing in high quality chemical pumps, and cooperating with reliable producers and suppliers.